This project aims to support the modern design of high-temperature alloys for automotive propulsion applications. The team's research will fill key knowledge gaps and reduce the time required to move from prototype high-temperature alloy development concepts to real-world deployment.

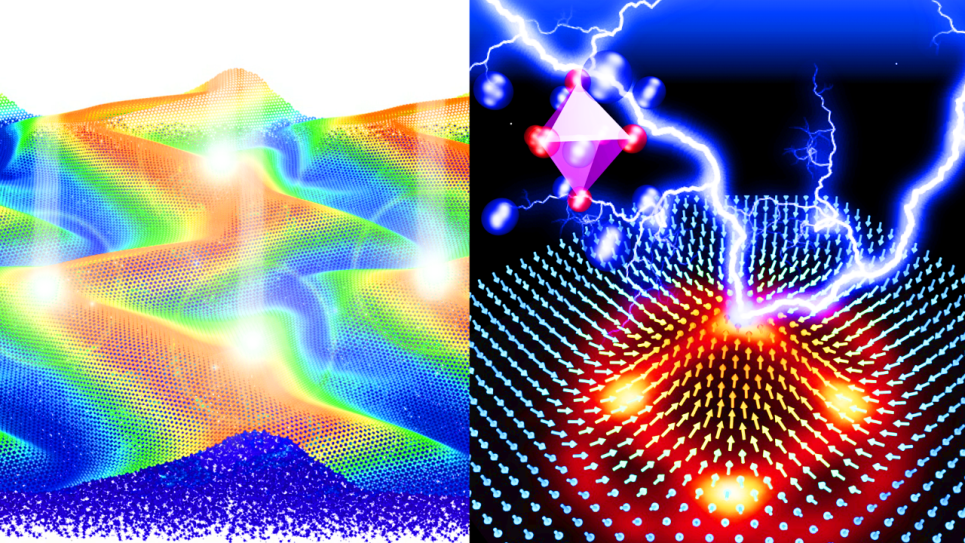

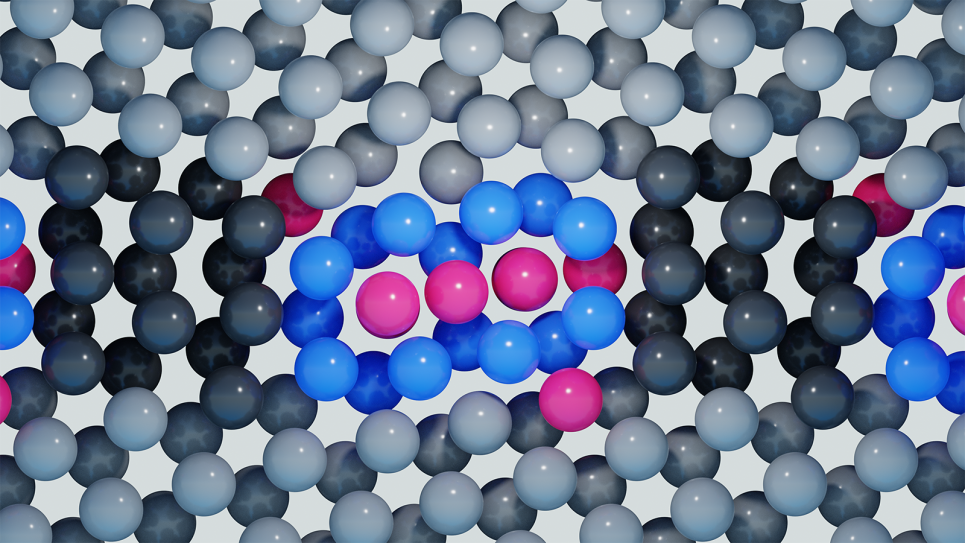

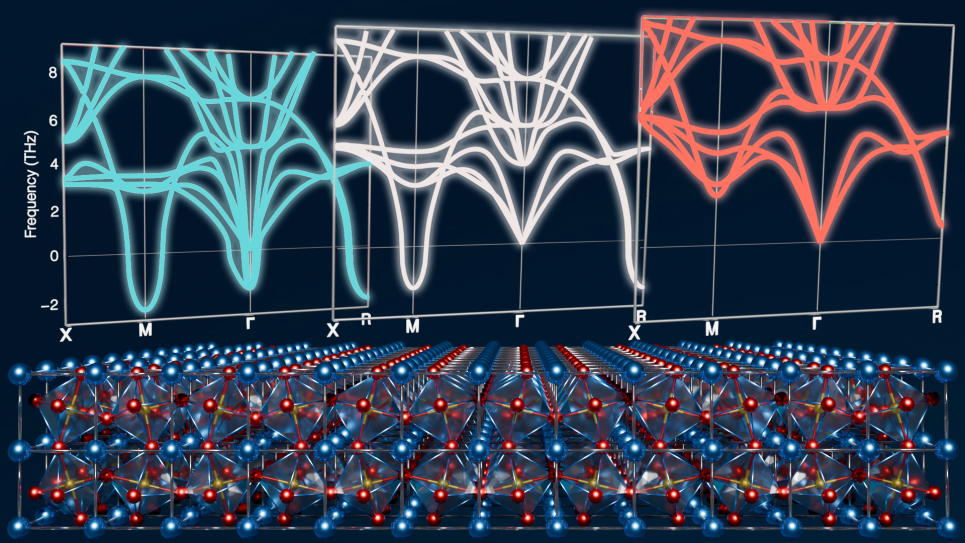

This end-station project aims to support the modern design of high-temperature alloys for automotive propulsion applications funded by DOE’s Vehicle Technologies Office (VTO) under Energy Efficiency and Renewable Energy (EERE). In its first year, the project has successfully demonstrated that a suite of state-of-the-art integrated computational materials engineering (ICME) software packages can significantly benefit from high-performance computing (HPC) resources for massive data acquisition. For example, first-principles calculations of nearly a thousand variants of supercells consisting of several hundreds of atoms, as well as hundreds of thousands of molecular dynamics simulations, can be completed within a week. This unprecedented pace of a large volume of high-quality data population has enabled rapid iteration of alloy design hypotheses generation/validation and coupling of physics in the context of materials data analytics.

Oak Ridge National Laboratory’s world-class alloy design expertise and advanced characterization across multiple DOE national laboratories will actively support the proposed HPC ICME tasks. The outcome of this project is to fill key knowledge gaps and reduce the timeframe from prototype high-temperature alloy development concepts to their real-world deployment.