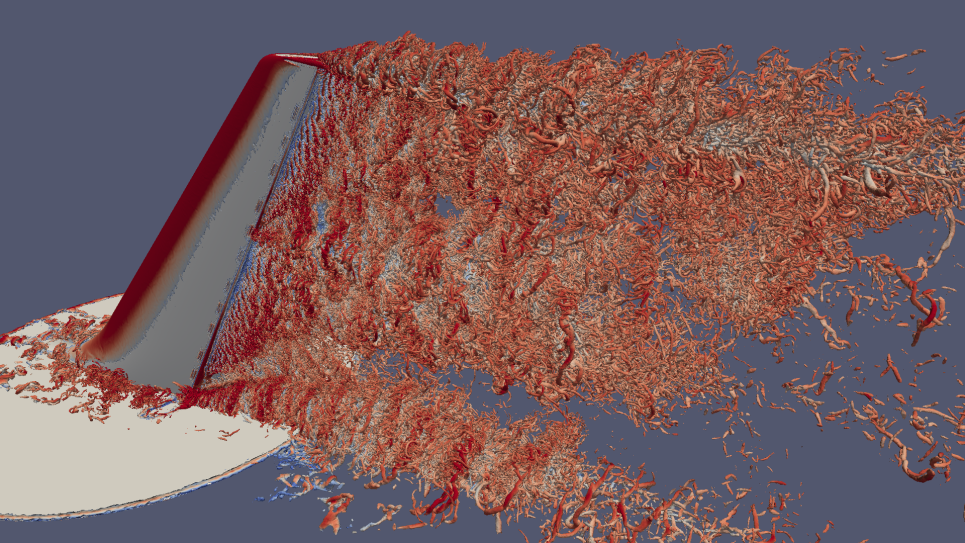

The design of new nuclear reactors, and the safe, efficient operation of existing reactors, can benefit from fundamental understanding of the bubbly two‐phase flows created as the water boils. The most accurate technique for these flows, Direct Numerical Simulation (DNS), captures all the length scales of turbulence in the flow. DNS of turbulent two-phase flows at a leadership computing facility allows achievement of unprecedented level of detail and can answer fundamental questions about the interaction between the complex and evolving interfaces of the bubbles and droplets and turbulence in the flow.

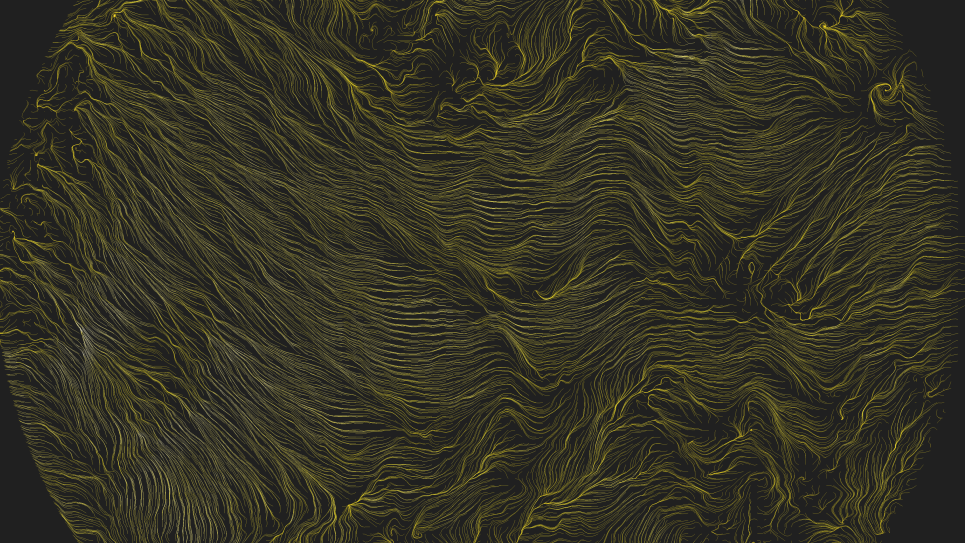

The detailed simulation of all turbulent structures using DNS approach as well as interface evolution in turbulent flows (in form of bubbles, droplets, wavy interfaces between liquid and steam in various flow regimes) will allow the collection of statistical information about two-phase flow parameters over an unprecedented range of conditions. Advanced data collection coupled with interface tracking will be used to process the large data sets.

Three subprojects will generate two-phase flow results highly relevant to nuclear reactor flows: (i) bubbly flow through pressurized water nuclear reactor fuel bundles with complex geometry spacers, (ii) complex two-phase flow regimes (slug and churn flow) as well as (iii) annular flows to the highest level of detail. Major parameters will be compared to experimental data for validation, while the higher order statistics produced by the simulations will bring new knowledge about two-phase flows, such as spectral information about gas/liquid interaction, bubbles and droplets contribution to the turbulence.

In this project, the complex physical phenomena will be captured in unprecedented detail. The level set interface tracking method and on-the‐fly mesh adaptation will be used to improve locally the mesh resolution of phase interface without the need to store intermediate files. In-situ co-processing of the data will also be used to accelerate the analysis. Advanced analysis tools will allow tracking every bubble and collect information about their behavior. This approach will allow partitioning and recognizing different patterns and phase interactions for two‐phase flows in complex geometries.

This data processing will generate information about vapor/liquid interaction, enabling the creation of new multiphase fluid models and closure laws that can be used in engineering simulations, allowing reliable application of multiphase computational fluid dynamics (M-CFD) to nuclear reactor systems. This will improve the safety margin predictions for existing reactors and facilitate the development and design of next-generation systems.