The efficiency of gas turbine engines is determined by combustion temperature: hotter combustion temperatures lead to more efficient operation. However, higher combustion temperatures require active cooling to avoid melting individual turbine components. One method for doing this is serpentine channels through the turbine blades. These channels route air from the compressor through the interior of the turbine blades to cool the turbine blade, preventing the surface from melting. Understanding air flow through these channels is critical to making the cooling as efficient as possible, as well as predicting the reliability of the turbine.

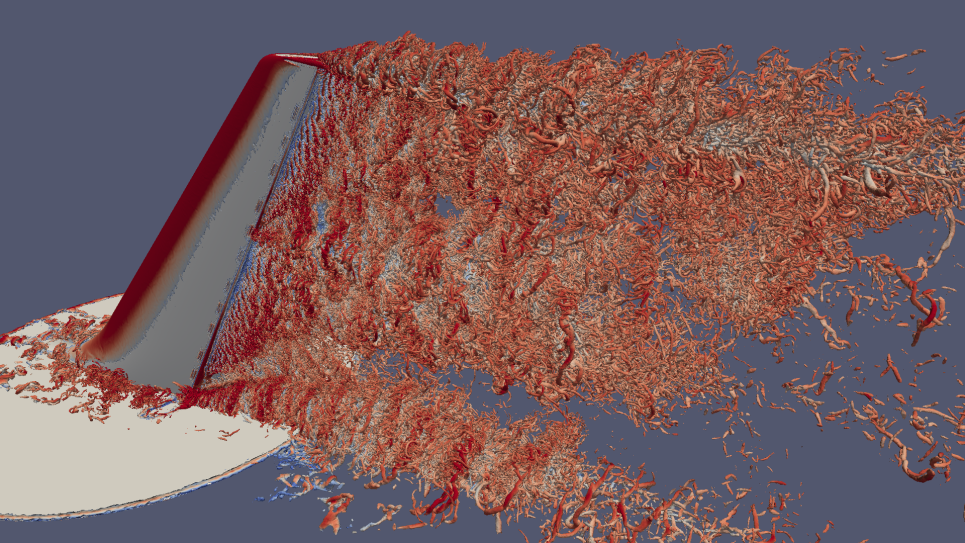

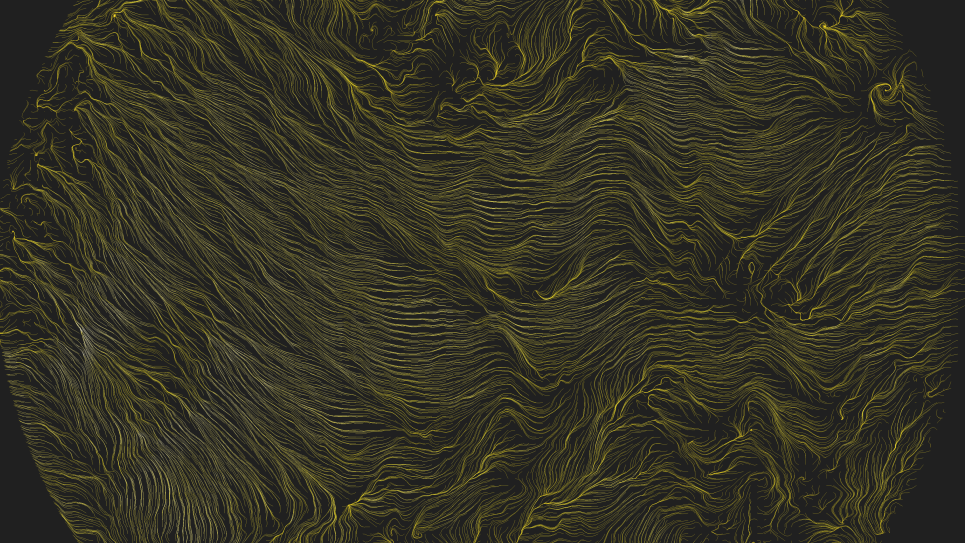

This project will used advanced computational fluid dynamics to simulate the turbulent flow and heat transfer through the serpentine cooling passages of a system that has been well-studied experimentally: the Stanford University Canonical Turbine Cooling Case. Researchers will use Large-Eddy Simulation (LES) methods to accurately include the effect of turbulent flow in the passage. This will allow investigators to determine how recirculation zones, turbulent intensities, heat transfer coefficients, coolant pressure drops and particle transport characteristics change as the flow conditions change. Initial simulations will be performed on non-rotating cases, allowing researchers to validate their results with direct comparison to experimental data. The researchers will then move to simulation rotating cases, to match actual turbine conditions. Including the transport of small particles, such as dust or dirt swept into the engine, will improve predictions of erosion in these channels. Because even small gains in efficiency over the number of gas turbines in operation yield large gains in fuel economy over an entire fleet of turbines, the results of this study have the potential to lead to large improvements in energy efficiency.