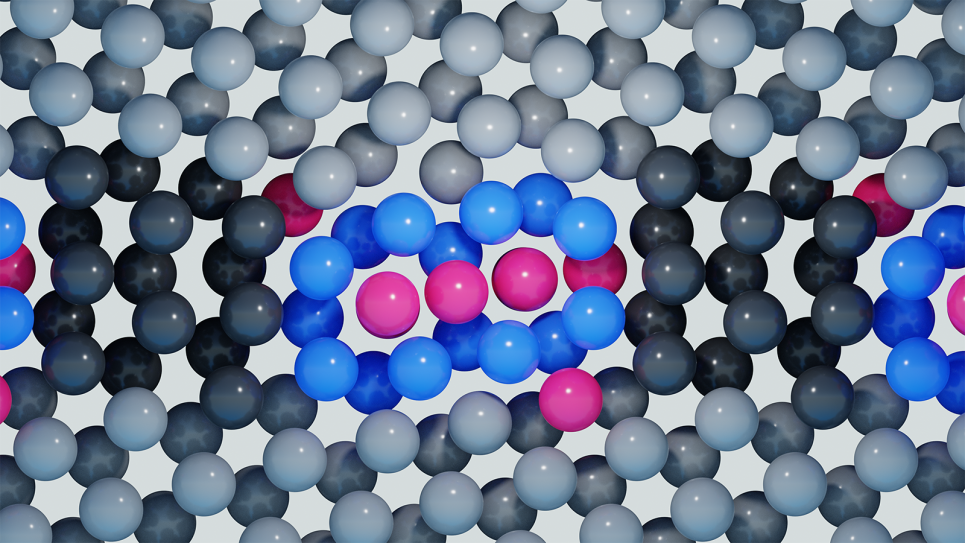

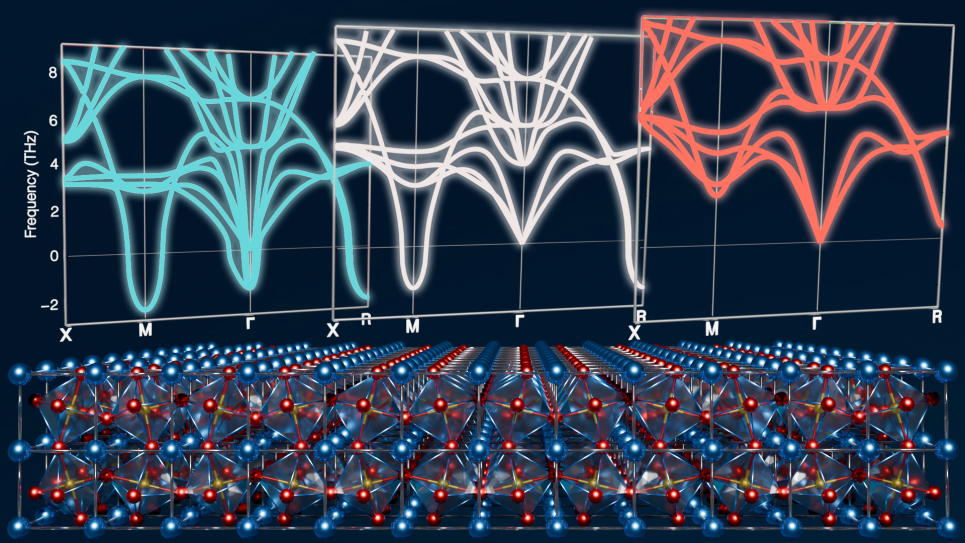

Concrete is the most widely used building material in the world, representing a 100 billion dollar industry in the US that is crucial for our nation’s physical infrastructure. There is now a strong interest in making concrete a more sustainable material by finding new ways to recycle it, and by changing its ingredients in order to reduce the amount of green house gas from its production (the manufacture of concrete’s key ingredient, cement, is responsible for about 8 % to 10 % of global CO2 production). As new mixture designs of concrete are developed to meet these needs, it is important to measure and control flow properties to satisfy performance specifications. Failure to control the flow of concrete on a job site can lead to significant cost overruns and months of delay by having to correct previous errors. Modeling the flow of concrete represents a great scientific and computational challenge. First, concrete is a dense (e.g. 50 % to 70 % by volume) suspension of aggregates (e.g. sand, gravel) in a non-Newtonian fluid matrix, with the aggregate size range usually several orders of magnitude. There are also significant effects from large aggregate shape variations that cannot be accounted for by modeling the aggregates as idealized spheres. As concrete undergoes shear flow, the shear rate dependent microstructures formed by the aggregates dynamically change as they are built up and destroyed over time. Measurement of the true rheological properties of fresh concrete is nearly impossible since the geometries of concrete rheometers (or indeed almost any suspension rheometer) and the characteristics of the suspensions themselves do not allow analytical solutions to relate torque and angular velocity to fundamental rheological parameters (yield stress, strain rate, plastic viscosity). Thus, it is necessary to compute the flow in these geometries in order to correctly interpret empirical measurements in terms of fundamental units. Our previous three-year INCITE award, granted in 2008, gave us the computing power to perfect our algorithms and to test parameters like system size and the width of the size distribution of the suspended particles in a large-scale parallel approach. We now seek to apply this capability to very large-scale parallel simulations needed to solve the problem of quantitatively extracting fundamental rheological parameters like stress and strain rate from measured quantities like torque and angular velocity in non-analytical rheometer and mixing geometries. Analysis and visualization of the simulated flow will enable us to develop a fundamental framework to understand important physical mechanisms that control the flow of such complex fluid systems. Results from this study will advance the science of dense suspensions and enable the measurement science needed for rheometer design for these systems. This will solve a critical outstanding problem in the cement and concrete industry, and will also have an enormous influence on the wide array of industries that use vane rheometers and mixers, from food processing to water treatment to coatings to pharmaceuticals.